|

The 2200 came from the factory with a cable-operated clutch that is agricultural in its action. Very heavy, particularly in comparison with the light effort needed to operate the brakes and steering. From 1979(?) to sometime in the mid eighties (again,?) Citroen used hydraulic clutch on the Prestige. Being Citroen, it would not suffice to use just a master-slave system like every other manufacturer on the planet. True to the original design principles of the DS, the effort to operate the clutch comes not from the driver, but from the engine. The driver's actuation of the clutch is more a regulation of the HP pressure acting on the slave cylinder, similar to the brake doseur. The Master Cylinder:

The Slave Cylinder / Clutch Actuator:

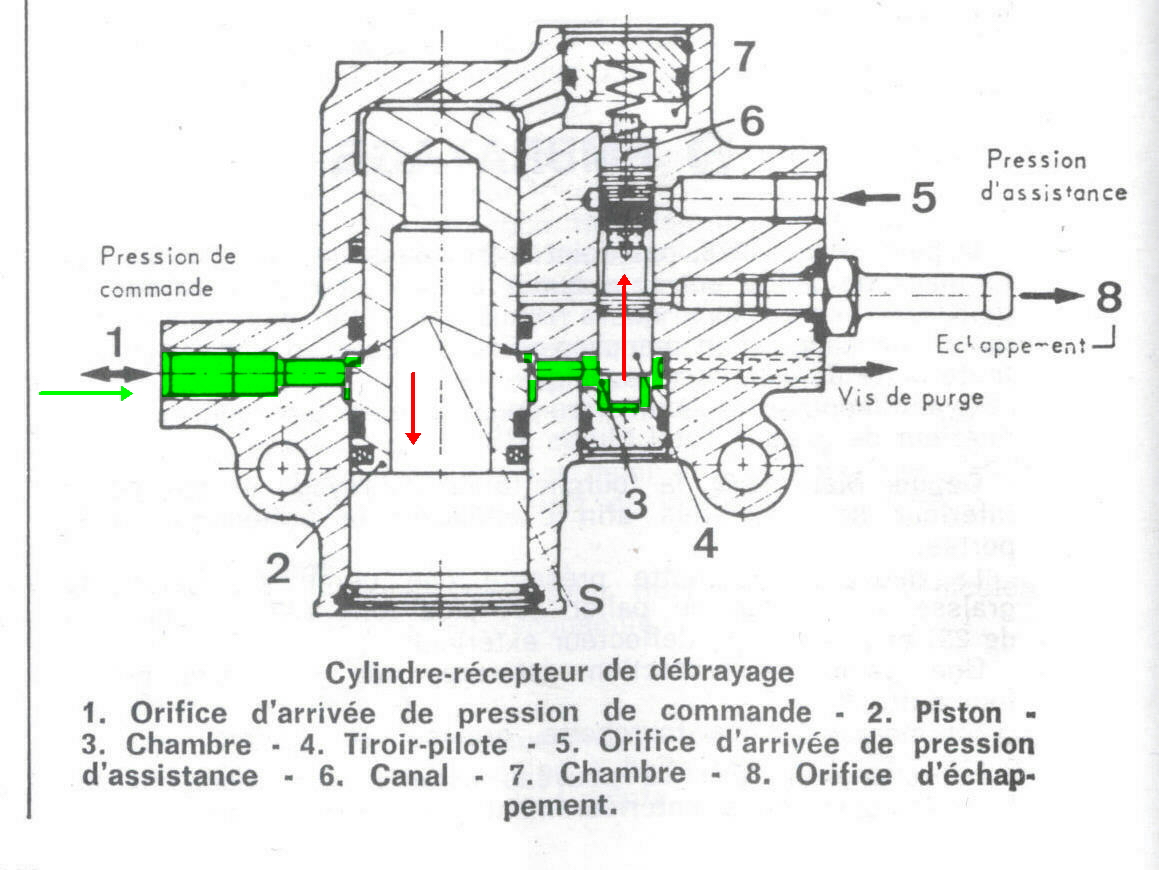

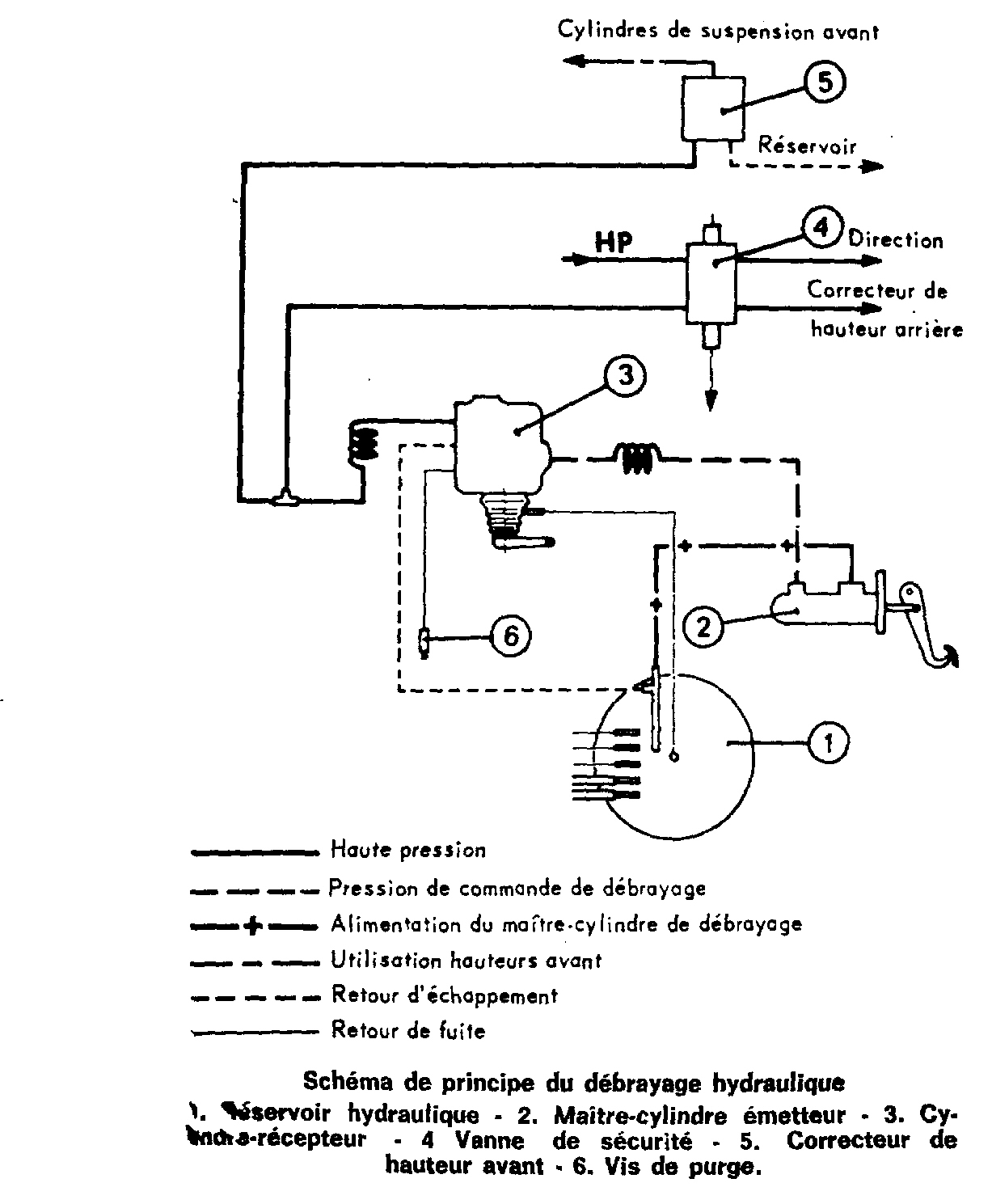

Here's a schematic from RTA:

Pressing on the clutch pedal operates the master cylinder (2). This actuates the slave cylinder and a valve that introduces HP to the slave cylinder (all inside 3). There is a Tee fitting in the line that supplies HP to the front suspension (5). This line comes from the priority valve (4). The slave cylinder dumps LHM back to the reservoir (1). This is through a hose similar to the return hoses from the doseur or the steering control unit. At the reservoir, there is a Tee fitting that provides LHM to the master cylinder. There is a bleeder line (6) from the slave cylinder, and a leak line from the rubber boot around the slave cylinder.

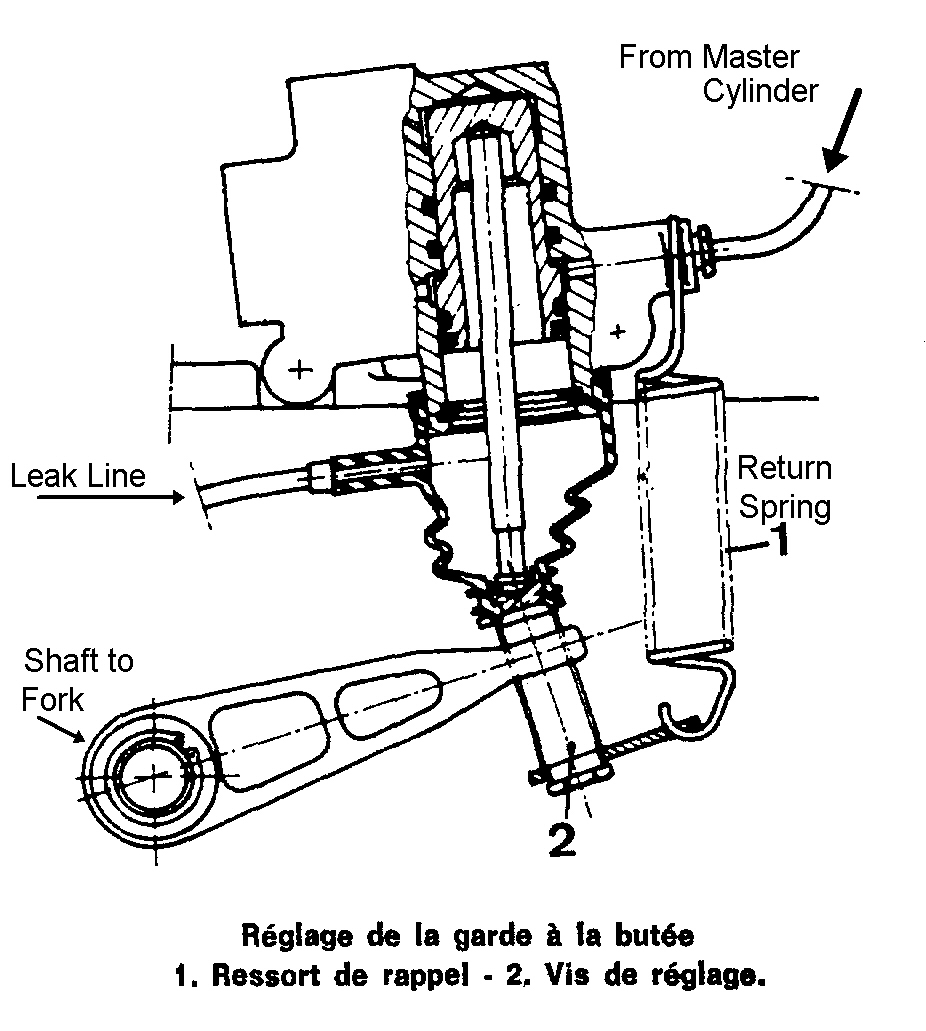

Here's the slave cylinder, which is located under the transmission casing. This diagram is as though you are looking up at the underside of the transmission.

What's happening inside the slave cylinder? The driver pushes the clutch pedal which increases pressure at point (1). This pushes the Piston (2) out and increases pressure in chamber (3). The increased pressure in chamber (3) pushes the slide-valve (4) in against the spring located in chamber (7). The slide-valve (4) closes the return line to the reservoir (8) and opens the line from the HP supply (5). (1) Connection from Master Cylinder (2) Piston (3) Chamber (4) Slide Valve (5) Connection to HP (6) Canal (7) Chamber (8) return to reservoir

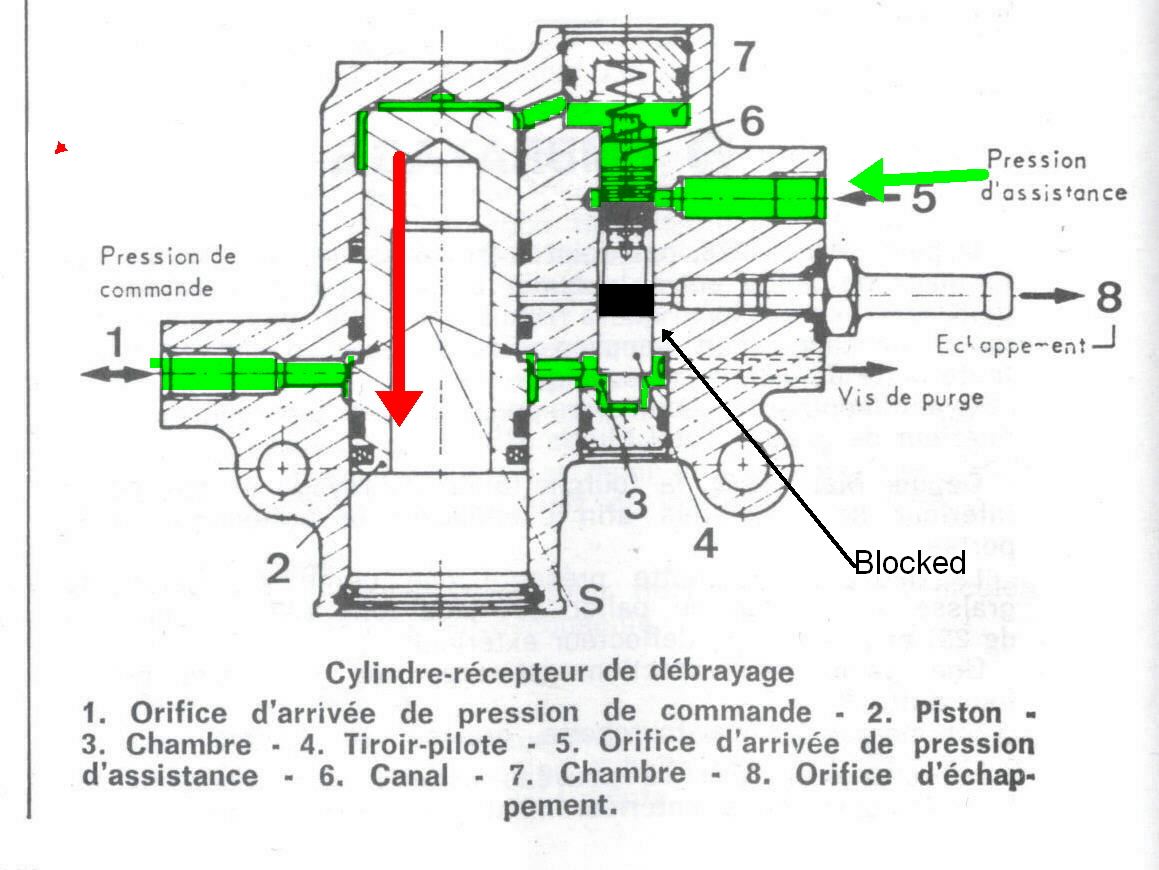

The slide-valve (4) has opened the HP connection, allowing LHM under pressure (5) to fill the chamber (7) through the canal (6). Chamber 7 is connected to the base of the piston (2) and the piston is assisted out by the HP.

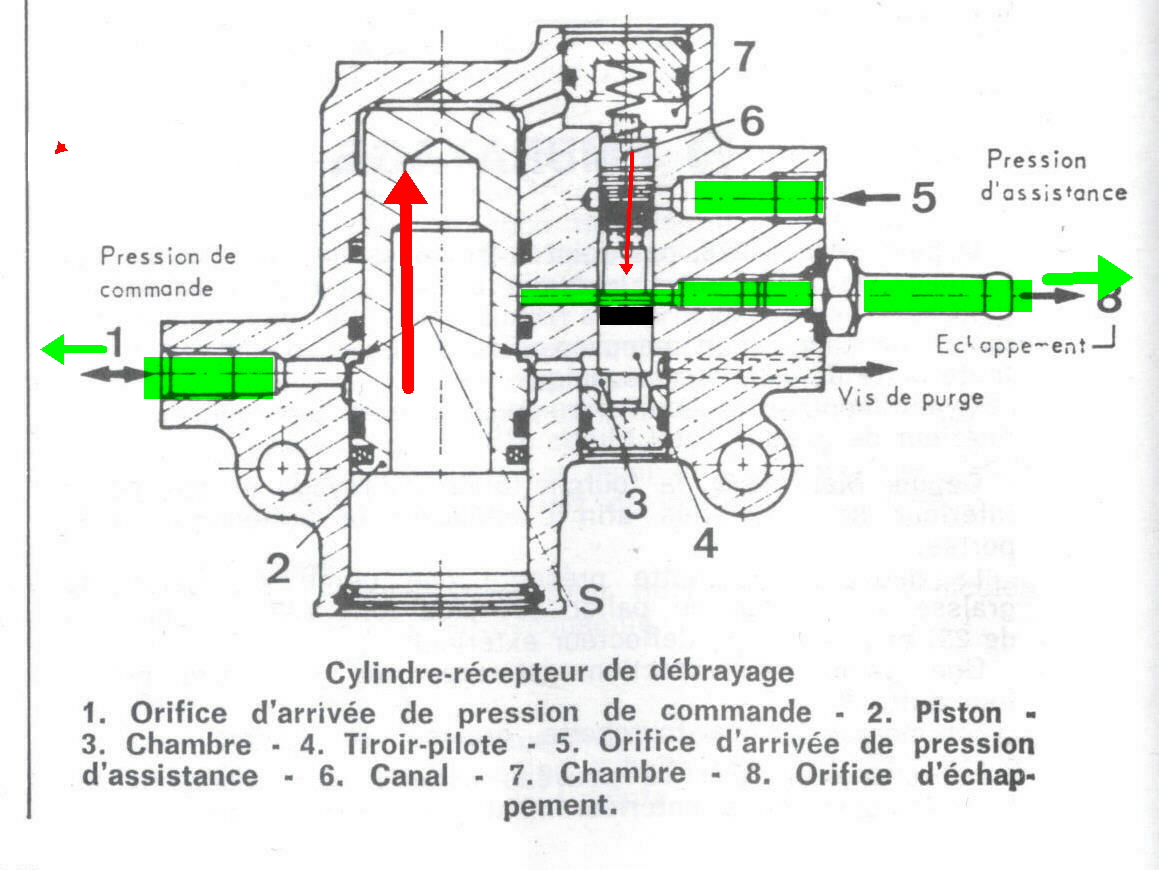

The clutch is released. Fluid flows back to the master cylinder(1), lowering the pressure in chamber (3). The spring in chamber (7) presses the slide valve (4) back into chamber (3). The slide valve closes the supply of HP(5), and opens the connection to the reservoir. LHM used to actuate the clutch returns (8) to the reservoir.

If the HP system fails, the clutch can still be actuated like any conventional hydraulic clutch, using the connection (1) and the chamber (3). Apparently the master cylinder creates enough volume of output to push the piston out. I guess this effectively acts as a closed system. Here is the bleeder fitting.

The hydraulic clutch requires a pedal mechanism that differs from the standard CX cable-operated clutch. A cable operated clutch necessitates that the pedal pull the cable to declutch. The master cylinder on the hydraulic system needs a pushing action. several photos of the cable and hydraulic pedal mechanisms. The cable mechanism is always on the left. The cable mechanism had a spring whose operation was typically Citroen; unusual, but elegantly effective. The point of maximum extension of the spring was midway through the clutch's travel. When declutching, the spring assisted the driver by pulling the pedal down to the stop. When reclutching, the spring pulled the pedal back to its engaged position.

Cable Clutch

Hydraulic Clutch

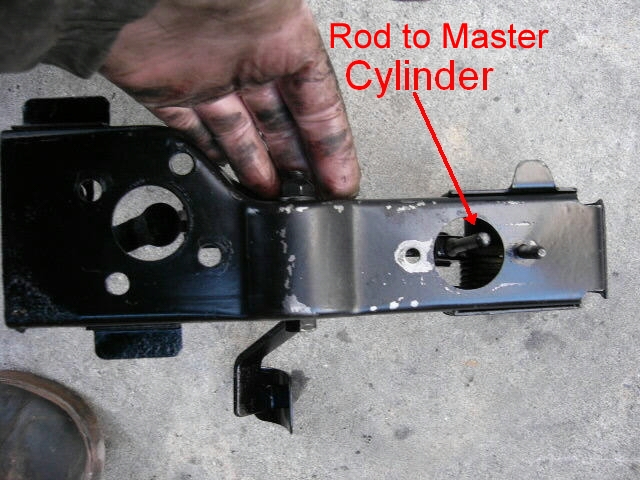

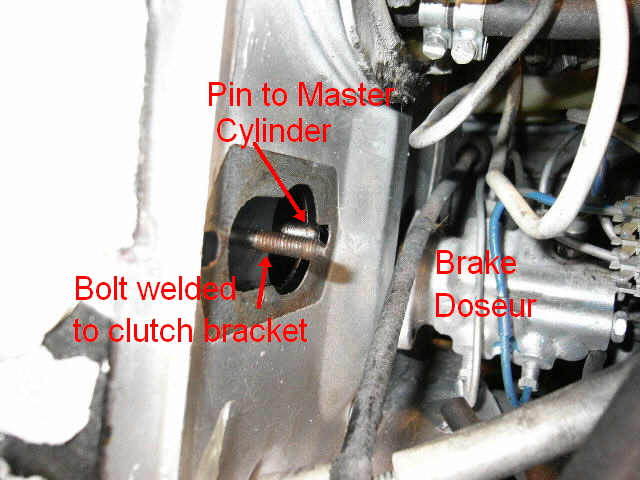

The new pedal mechanism got a good brushing with a wire brush and dremel to get the rust off, then a new coat of high-gloss black Rustoleum. View from the engine side of the firewall. I was test-fitting the clutch at the time. Don't worry, I cleaned the rust off the threads before the final installation.

As installed. New fasteners, always.

|

|||||||||||||

image

from RTA

image

from RTA